Torsional vibration is angular vibration of an object—commonly a shaft along its axis of rotation. Torsional vibration is often a concern in power transmission systems using rotating shafts or couplings where it can cause failures if not controlled. A second effect of torsional vibrations applies to passenger cars. Torsional vibrations can lead to seat vibrations or noise at certain speeds. Both reduce the comfort. In ideal power generation, or transmission, systems using rotating parts, not only the torques applied or reacted are "smooth" leading to constant speeds, but also the rotating plane where the power is generated (or input) and the plane it is taken out (output) are the same. In reality this is not the case. The torques generated may not be smooth (e.g., internal combustion engines) or the component being driven may not react to the torque smoothly (e.g., reciprocating compressors), and the power generating plane is normally at some distance to the power takeoff plane. Also, the components transmitting the torque can generate non-smooth or alternating torques (e.g., elastic drive belts, worn gears, misaligned shafts). Because no material can be infinitely stiff, these alternating torques applied at some distance on a shaft cause twisting vibration about the axis of rotation.

Form more information, view attachment: Rotational Vibration Measurements using Laser Doppler Vibrometry: Comprehensive Theory and Practical Application

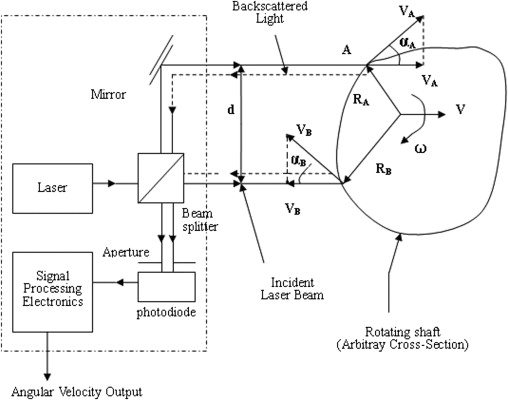

Laser light has an inherent property that makes laser technology ideally suited for use in the torsional vibrometer. When a laser beam is split and subsequently recombined, a well-defined phase relationship still exists in the recombined beam, even if its component beams have traveled different distances. This is known as temporal coherence, and the maximum path difference over which it holds true is the coherence length. A schematic of the electronic and optical components in the laser torsional vibrometer is shown in Fig. 1. The heart of the system is a low power (< 1.5 mW) laser. The laser beam is split into two equal-intensity parallel beams separated by a distance `d`.

`d = R_Acosα_A+R_Bcosα_B`

Where `R_A` is transient rotating radius of point A, and `R_B` is that of point B. The beams strike the shaft surface at point A and B. The instantaneous velocity at each of points A and B, with respect to the axis of rotation, is `V_A` and `V_B`, respectively. The shaft itself also has an instantaneous velocity of `V`. Each beam sees only the velocity in one direction:

`V_A = −V_Acosα_A−V = −omegaR_Acosα_A−V`

`V_B = V_Bcosα_B−V = omegaR_Bcosα_B−V`

and is thus frequency shifted:

`f_A = 2V_A/lambda` and `f_B = 2V_B/lambda`

where `lambda` is the wavelength of laser. This signal contains the required angular vibration information. It is not practical to demodulate the signal directly. When the beams arrive at the photodiode they heterodyne, producing an output current that is modulated at the beat frequency `f_D`, that is, the difference between the frequencies of the Doppler-shifted beams:

`f_D = f_B−f_A = 2lambda(V_B−V_A) = (2omega/lambda)(R_Bcosα_B+R_Acosα_A) = 2omegad/lambda`

Thus, the beat frequency is directly proportional to the shaft speed (`omega`) and is independent of any solid body motion of the shaft. If the plane of the laser beams is not perpendicular to the shaft axis, then `f_D` is also a function of `costheta`, where `theta` is the angle between the plane of the laser beams and the plane perpendicular to the axis of shaft rotation. The laser torsional vibration meter is designed to simplify the measurement of torsional vibration. The fitting and calibration of conventional torsional transducers requires substantial machinery downtime. Attachment of the retroreflective tape is quick, thus minimizing machinery downtime and simplifying the measurment process.

To measure and plot the torsional vibrations of an engine under various load conditions and constant rotational speed using a rotational laser vibrometer.

This remote triggered virtual lab is accessible over the internet you have to use the login user id and password provided to you when you registered for this experiment.

Please refer to the detailed procedure sent to you by email. You need to have team viewer software installed in your computer with an high speed internet access. You'll be able to get visual feed from the lab where the experimental setup is physically placed while the experiment is being conducted you have the option to access and retrieve the experimental data over the internet to your computer for further processing.

For working from the lab , one has to switch on the water pump, the motor, fuel supply, and the control panel.Once the computer starts, you need to open the already installed EPA software. Then you have to crank the engine. Adjust the dynamometer load control for varying the torque.

Precautions

- Shoes are a must in the lab. It protects us from electrical shocks and from any heavy device falling on our feet.

- The nut closing the opening of fuel pipe must be opened.

- No bubble must be present in the fuel tube.

- The water flow rate must be around 100.

- The emergency door must be kept open.

- The water tank must be full and must have pure water.

Fig: RLV - Rotating Laser Vibrometer

Simulator content...

Books

- M L Mathur and R P Sharma, "A Course in Internal Combustion Engines", Dhanpat Rai & And Sons(1994)

- C R Fergusan and A T Kirkpatrick, "Internal Combustion Engines", John Wiley & Sons(2001)

- V Ganesan, "Internal Combustion Engines", Tata McGraw Hill(2003)

- J B Heywood, "Internal Combustion Engine Fundamentals", McGraw Hill.(1999)

- S Srinivasan, "Automotive Engines", Tata McGraw Hill.(2001)

- Amiya R Mohanty, "Machinery Condition Monitoring Principles and Practices", CRC Press(2014)

Web Resources

- http://en.wikipedia.org/wiki/Internal_combustion_engine

- http://machinedesign.com/fea-and-simulation/new-techniques-predict-machine-vibration

- http://mechteacher.com/otto-cycle-mean-effective-pressure-derivation/

- http://web.itu.edu.tr/~sorusbay/ICE/index_files/LN07.pdf

- http://en.wiktionary.org/wiki/crank_angle

- http://enginemechanics.tpub.com/

- http://www.howstuffworks.com/

- http://www.eng.fsu.edu/

- https://mysaclink.csus.edu/

- http://www.w3schools.com/html/

- http://www.polytec.com/vibrometers

- http://www.britannica.com/EBchecked/topic/371842/mechanical-efficiency