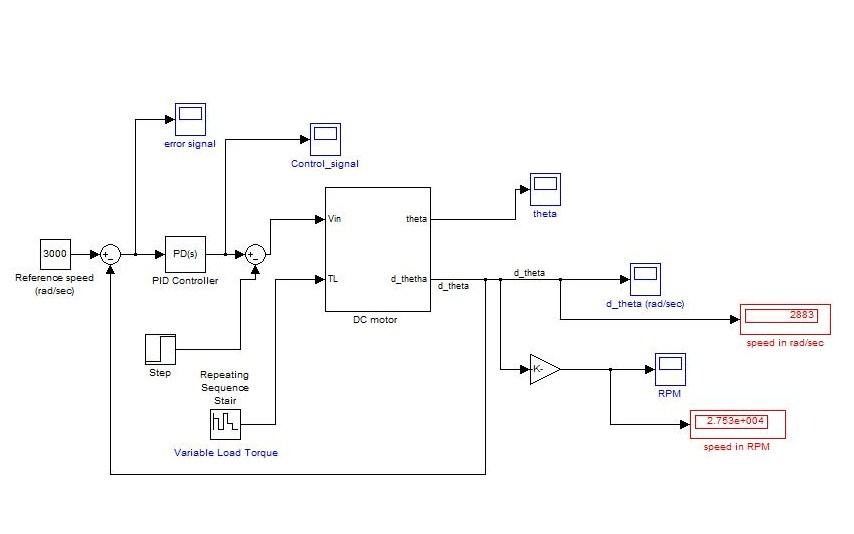

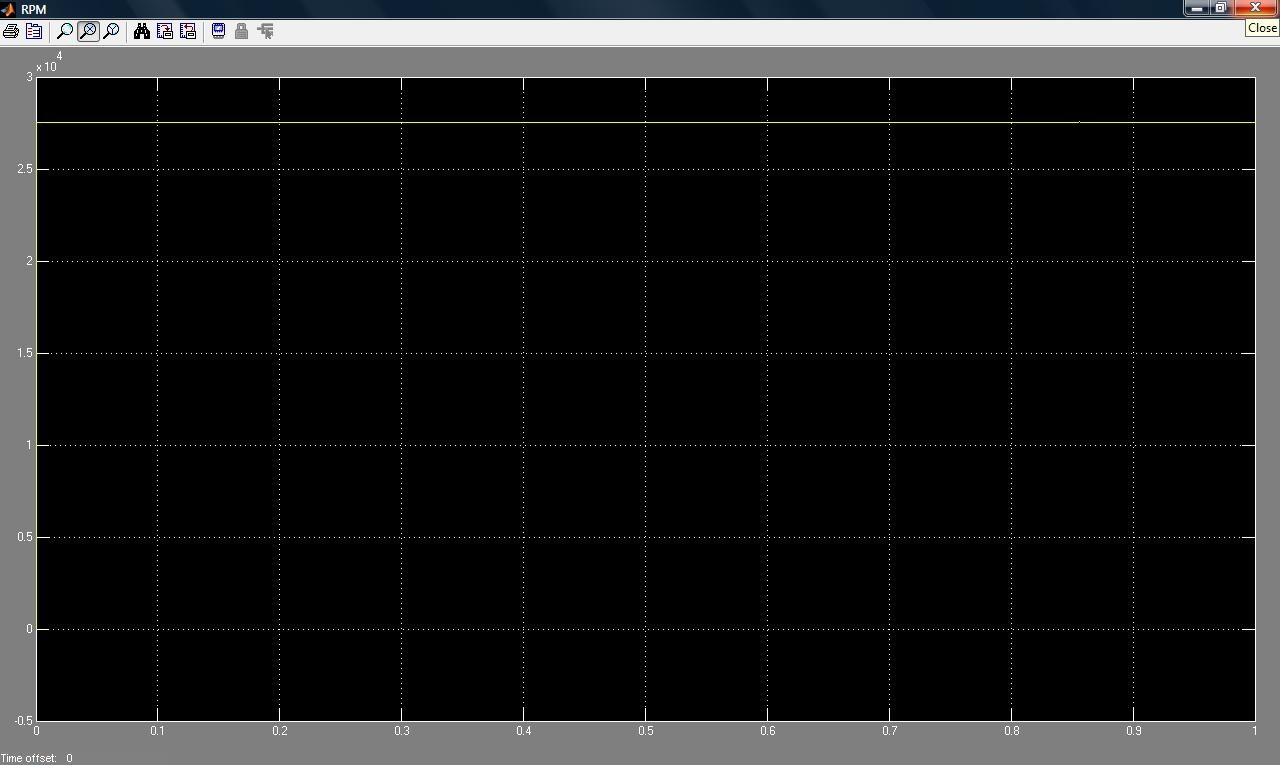

CLOSED LOOP CHARACTERISTICS OF DC MOTOR

PROPORTIONAL AND DERIVATIVE CONTROL

Proportional-Derivative control is useful for fast response controllers that do not need a steady-state error of zero.

The effect of proportional and derivative actions is described as below:

Proportional Action

Proportional action provides an instantaneous response to the control error. This is useful for improving the response of a

stable system but cannot control an unstable system by itself. Additionally, the gain is the same for all frequencies leaving

the system with a nonzero steady-state error.

Derivative Action

Derivative action acts on the derivative or rate of change of the control error. This provides a fast response, as opposed to

the integral action, but cannot accommodate constant errors (i.e. the derivative of a constant, nonzero error is 0). Derivatives

have a phase of +90 degrees leading to an anticipatory or predictive response. However, derivative control will produce large

control signals in response to high frequency control errors such as set point changes (step command) and measurement noise.

Proportional-Derivative (PD) Control

Proportional-Derivative or PD control combines proportional control and derivative control in parallel.

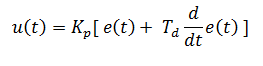

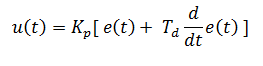

It can be mathematically expressed as:

where

is the Proportional control gain and

is the derivative time.

Design Considerations

With proportional controller alone the shape of the open loop transfer function will be the same as the plant but the

overall magnitude of the plant will be higher. With derivative control the open loop transfer function above the frequency of

the derivative (zero) will have a +20 dB/decade slope. The phase will gain +90 deg above the zero as well.

Proportional control will follow the noise and amplify it by the magnitude of the controller. Derivative control will

amplify noise by following the difference between two noisy error signals. One should keep these things in mind while designing

a PD control.