Theory

The first step in the analysis of control system is to derive the mathematical model of the complete system. This would help in understanding the working of the complete system.

The Plant (Oven)

The plant to be controlled is an electric oven, the temperature of which must adjust itself in accordance with the reference or command. This is a thermal system which basically involves

transfer of heat from one section to another. In present case we are interested in transfer of heat from heater coil to the oven and leakage of heat from the oven to the atmosphere.

Here, a lumped parameter model is considered. For precise analysis, a distributed parameter model must be used. Another difficulty associated with temperature control system is that

the temperature rise is produced by energy input, which is controllable but the temperature fall is due to heat loss, which is uncontrollable. There are three modes of heat transfer

viz. conduction, convection, radiation. Heat transfer through radiation may be neglected in the present case since the temperatures involved are quite small.

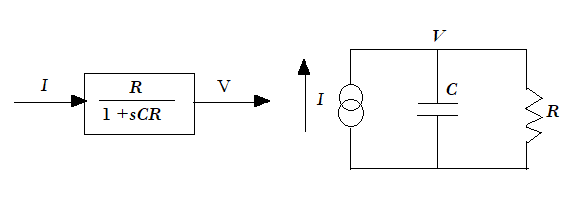

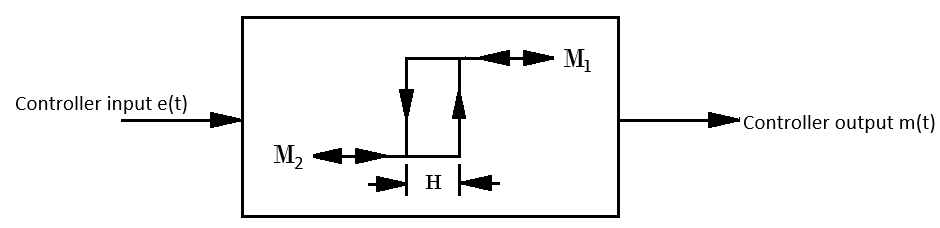

Fig. 1. Electrical Analogy

Fig. 1. Electrical Analogy

Fig. 2. Closed loop Temperature Control System

Fig. 2. Closed loop Temperature Control System

For conductive and convective heat transfer,

$$ {\Theta = \alpha \Delta T} \tag{1}$$

where,

Θ = Rate of heat flow in Joule/sec.

Δ

T = Temperature difference in °C

α = Constant

Under assumption of linearity, the themal resistance is defined as,

$$R = \frac{ Temperature \ difference \ }{rate \ of \ heat \ flow}$$

$$ = \frac{\Delta T}{\Theta} = \frac{1}{\alpha} $$.

This is analogous to electrical resistance defined by

I = V/R. In a similar manner thermal capacitance of the mass is defined by

$$ \Theta = C \ \frac{d(\Delta T)}{dT} \tag{2}$$

which is analogous to the

V - I relationship of a capacitor, namely

I = C dV/dt. In the case of heat,

C = Rate of heat flow / Rate of temperature change.

The equation of an oven may now be written by combining the equations 1-2, implying

that a part of the heat input is used in increasing the temperature of the oven and the rest goes

out as loss. Thus

$$ \Theta = C \ \frac{dT}{dt} + \frac{1}{R} \ T, \tag{3}$$

with the initial condition

T (t = 0) = Tamb. Now, taking Laplace transform with zero

initial condition,

$$ \frac{T(s)}{\Theta(s)} = \frac{R}{1+sCR} \tag{4}$$

An analogous electrical network and block diagram may be drawn as shown in fig-1, defined

by the equation

$$I = C \frac{dV}{dt} + \frac{V}{R} \tag{5}$$

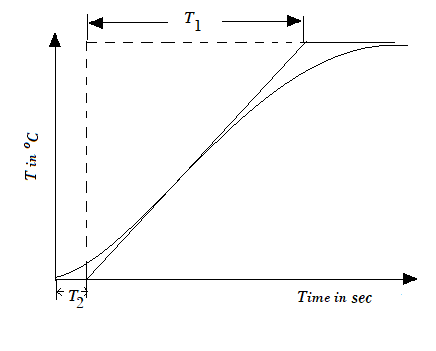

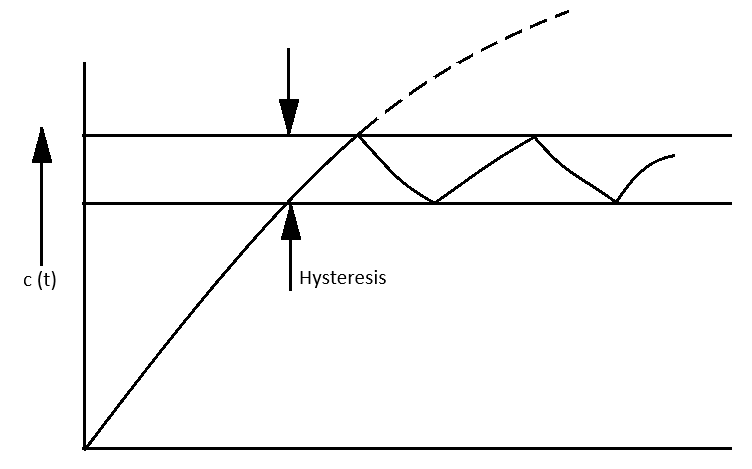

The temperature rise in response to the heat input is not instantaneous. A certain amount

of time is needed to transfer the heat by convection and conduction inside the oven. This requires a delay or transportation lag term,

e-sT2, to be included in the transfer

function, where

T2 is the time lag in seconds.

The open loop transfer function of the plant is given by

$$ G(s)= \frac{ke^{-sT_2}}{1+sT_1} \tag{6}$$

where

k = DC gain of the system,

T1 = Time Constant ,

T2 = Delay Time

Fig. 3. Open loop response of the oven

Fig. 3. Open loop response of the oven

Controller

Basic control actions commonly used in temperature control systems are,

1) Proportional

2) Proportional-Integral

3) Proportional-Integral-Derivative

4) ON-OFF or relay

These are described below.

Proportional Controller

Proportional controller is simply an amplifier of gain

kp which amplifies the error signal and passes it to the actuator.

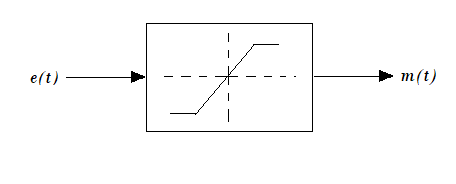

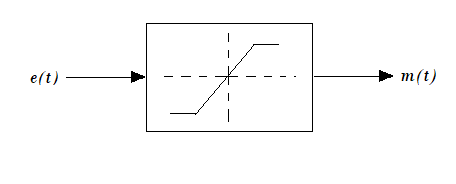

A typical proportional controller may have input output characteristics as shown in Fig. 4.

Such controller gives a non-zero steady state error to step input for a type-0 system. The proportional block in the system consists of a

variable gain amplifier having a maximum value,

kp max of 20.

Fig. 4. P Controller

Fig. 4. P Controller

Proportional Integral Controller

Mathematical equation of such a controller is given by,

$$ m(t)= k_{p} e(t)+ k_i \int_{0}^{t}e(t)dt = k_p e(t)+\frac{1}{T_i}\int_{0}^{t}e(t)dt \tag{7}$$

It may be easily seen that this controller introduces a pole to origin, i.e. increases the system type by unity. The steady state error therefore gets reduced.

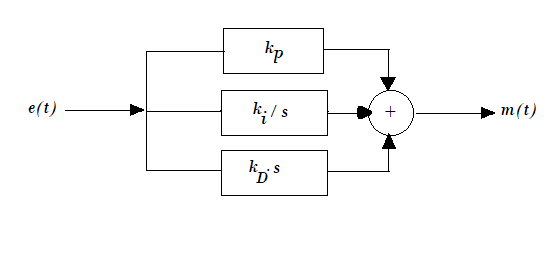

A block diagram representation is shown in fig 5. Qualitatively,

any small error signal

e(t), present in the system, would get continuously

integrated and generate actuator signal

m(t) forcing the plant output to exactly correspond to the reference input so that error is zero. In practical system the

error may not be zero due to imperfections in an electronic integrator caused by biased current needed, noise ,drift present and leakage of the integrator

capacitor. The integral block in the present system is realized with a circuit, that has a transfer function

$$ G_{r}(s)=\frac{1}{41 \ s}=\frac{k_{i}}{s} \tag{8}$$

The integral gain is therefore adjustable in the range 0 to 0.024 (approx).

Fig. 5. PI Controller

Fig. 5. PI Controller

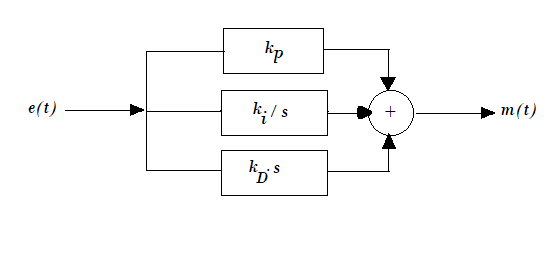

Proportional Integral Derivative Controller

The governing equation here is,

$$ m(t)= k_{p} e(t)+ k_i \int_{0}^{t}e(t)dt + k_D\frac{de(t)}{dt} = k_p e(t)+\frac{1}{T_i}\int_{0}^{t}e(t)dt + T_D\frac{de(t)}{dt} \tag{9}$$

In laplace transform domain,

$$ \frac{M(s)}{E(s)}=(k_p + \frac{1}{T_i \ s} + T_D \ s) \tag{10}$$

A simple analysis would show that the derivative block essentially increases the damping ratio of the system and therefore improves the dynamic performance

by reducing the overshoot. The PID controller therefore helps in reducing the steady state error with an improvement in the transient response.

The derivative block in the present system is realized with a circuit, that has a transfer function

$$ G_{D}(s)=19.97 \ s \ (approx) \tag{11}$$

The derivative gain is therefore adjustable in the range of 0 to 20 approximately.

PID controller is one of the most widely used controller because of its simplicity. By adjusting its coefficients

kp, ki, kD

the controller can be used in variety of systems. The process of setting the controller coefficients to suit a given plant is known as tuning. There are many methods

of tuning a PID controller. In present experiment, the method of Ziegler-Nichol has been introduced which is suitable for the oven Control System.

According to the Ziegler-Nichol rule,

in P control,

$$ k_p = (\frac{1}{k})\frac{T_1}{T_2} \tag{12}$$

in PI control,

$$ k_p = (\frac{0.9}{k})\frac{T_1}{T_2} \tag{13}$$

$$ k_i = \frac{1}{3.3T_2} \tag{14}$$

in PID control,

$$ k_p = (\frac{1.2}{k})\frac{T_1}{T_2} \tag{15}$$

$$ k_i = \frac{1}{2T_2} \tag{16}$$

$$ k_D = 0.5T_2 \tag{17}$$

P-control potentiometer setting:

Calculate the value of

kp for each type of control using the Ziegler-Nichol rule. The formula for

kp is for an unity feedback system and has the

dimension of Volts/°C. In the present unit a temperature sensor having sensitivity of 10mV/°C (0.01 V/°C) is used between oven output and controller input. Hence, divide the

kp calculated above by 0.01 and then

by the

kp max value (20) to get the potentiometer setting.

I-control potentiometer setting:

Calculate the value of

ki for each type of control using the Ziegler-Nichol rule. Then divide that calculated value by

ki max value (0.024) to get the potentiometer setting.

D-control potentiometer setting:

Calculate the value of

kD for each type of control using the Ziegler-Nichol rule. Then divide that calculated value by

kD max value (23.5) to get the potentiometer setting.

Fig. 6. PID Controller

Fig. 6. PID Controller

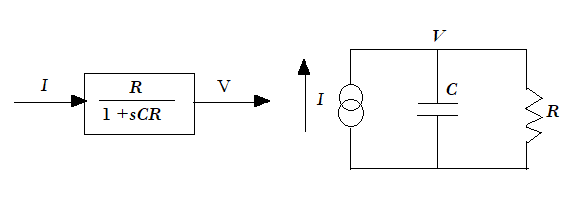

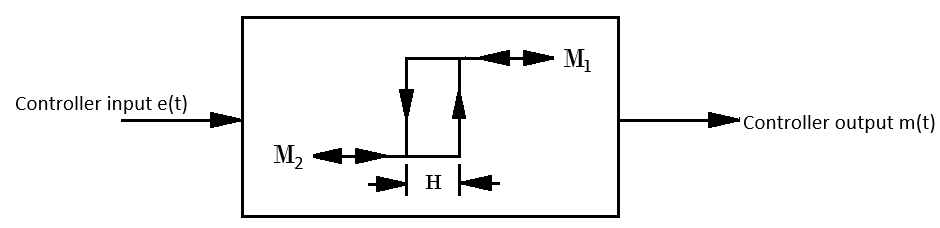

ON-OFF or Relay type controllers :

It is also reffered to as two position controllers, consist of a simple and inexpensive switch/relay and are, therefore, used very commonly in both industrial and domestic control systems.

Typical applications include air-conditioner and refrigerators, ovens, heaters with thermostat. Solenoid operated two position valves are commonly used in hydraulic and pneumatic systems.

The basic input-output behaviour of this controller is shown in Fig. 7. The two positions of the controller are

M1 and

M2, and

H is the hysteresis or differential gap.

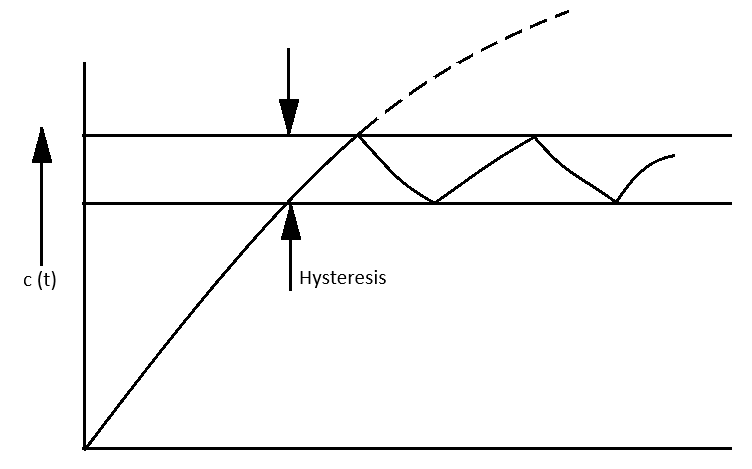

The hysteresis is necessary, as it enables the controller output to remain at its present value till the input or error has increased a little beyond zero. Hysteresis helps in avoiding too frequent

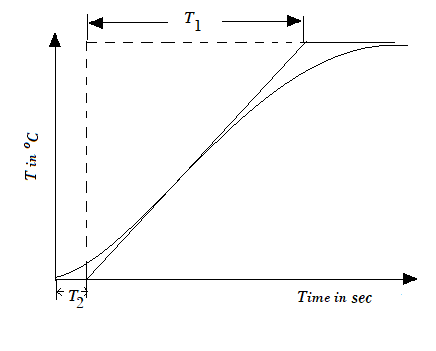

switching of the controller, although a large value results in greater errors. The response of the system with ON-OFF controller is shown in Fig. 8. Describing function technique is a standard method

for the analysis of non-linear systems, for instance, one with an ON-OFF controller.

Fig. 7. ON-OFF Controller

Fig. 7. ON-OFF Controller

Fig. 8. Response of ON-OFF control system

Fig. 8. Response of ON-OFF control system